ThePickPath consiste, en fonctionnalité de base, à réduire les déplacements dans un entrepôt.

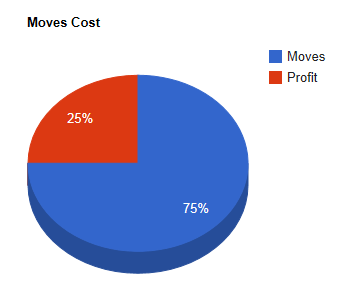

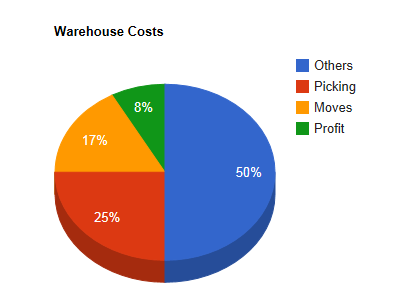

Sachant que l’activité de picking constitue, en moyenne, 50 % de l’activité globale d’un magasin et que les trajets représentent environ 50 % du temps, les coûts peuvent être réduits considérablement, car si on peut réduire le temps de trajet, on joue sur un facteur très important des coûts en logistique. En fonction du niveau de productivité/optimization du magasin (chemin de picking de base bien pensé, réorganisation ABC), l'outil va permettre de réduire les déplacements jusqu'à 30 %.

Pour plusieurs tâches de picking sur le même opérateur, thePickPath optimise l’ordre d’exécution des tâches.

Pour un shift complet de picking, thePickPath répartit le travail entre les différents opérateurs.

Dans de nombreuses situations de contraintes(poids, volume, fragilité, livraisons...), une priorité est indiquée sur les articles. ThePickPath prendra alors en compte ces priorités dans son calcul.

Le magasin est schématisé en vue aérienne. L'algorithme se base sur cette structure simplifiée. Les emplacements de taille variable ne sont pas pris en compte car leur influence est réduite sur le temps de déplacement.

ThePickPath est également indiqué pour réduire les déplacements dans d’autres activités : mise en stock, prélèvement de palettes complètes, réappro/achalandage, déplacements internes.